Why Precision Machining Matters in Aluminium Extrusion Assemblies

Published by: ALUTimes | Date: July 10, 2025

Introduction

Precision machining is the backbone of reliable aluminium extrusion assemblies. Whether it’s for aerospace frames, electric vehicle enclosures, or architectural systems, the need for exact cuts, accurate holes, and seamless joins is critical. In this article, we explore why precision machining is essential for aluminium profiles and how it ensures quality, safety, and performance in modern applications.

What Is Precision Machining in Aluminium Extrusions?

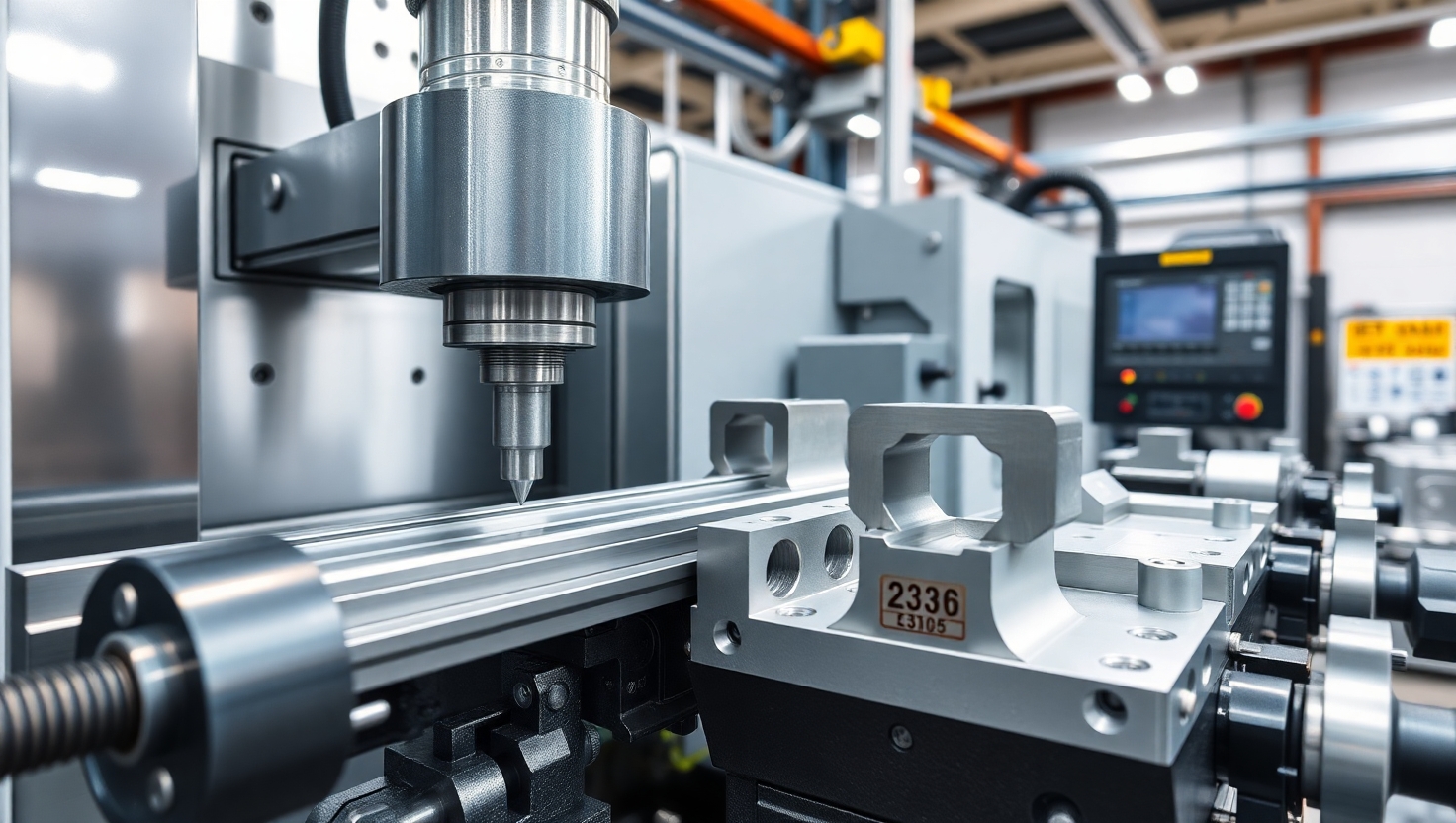

Precision machining involves using tools like CNC mills, routers, and lathes to shape, drill, or cut aluminium extrusions to highly accurate tolerances. It transforms raw or semi-finished extruded profiles into final parts ready for assembly or integration, meeting exact engineering requirements.

Why Precision Matters in Extrusion Assemblies

- Structural Integrity: In load-bearing applications, any deviation in machining can lead to weak points or misalignment.

- Interchangeability: Precise parts ensure compatibility with standard fittings and modular designs.

- Speed of Assembly: Tightly machined parts reduce rework, manual fitting, and downtime during assembly.

- Visual Appeal: Especially in architectural aluminium, gaps, uneven cuts, or rough finishes are unacceptable.

- Product Longevity: Properly machined components reduce wear and tear, enhancing durability.

Applications Where Precision Is Critical

- Aerospace: Frames, brackets, and panels with micron-level tolerances

- Automotive: Battery trays, crash structures, and sensor mounts

- Electronics: Heat sinks and enclosures for circuit boards

- Architecture: Curtain walls, window frames, and modular facades

- Medical: Lightweight, corrosion-resistant instrumentation

Common Precision Machining Techniques

- CNC Milling: For complex geometries and tight tolerances

- Drilling and Tapping: For bolt holes and threaded inserts

- Deburring: Ensures clean edges and eliminates safety risks

- Facing and Slotting: For clean joining surfaces

- 5-Axis Machining: Used for complex aerospace or automotive parts

Precision Machining vs. Standard Fabrication

Standard fabrication may suffice for non-critical or cosmetic uses. However, for safety-critical applications, only precision machining offers the necessary repeatability, accuracy, and quality assurance. Investing in precision techniques upfront reduces long-term costs from failures, replacements, or recalls.

Challenges in Machining Aluminium Extrusions

- Softness: Aluminium can deform or clog tooling if not managed correctly.

- Heat Buildup: Requires proper coolant systems to avoid warping.

- Thin Walls: Delicate extrusions need special fixtures to prevent vibration.

- Dimensional Stability: Consistency is essential across batches.

Quality Control in Precision Machining

- Use of coordinate measuring machines (CMM)

- Laser scanners for profile validation

- Caliper and micrometer checks

- Statistical Process Control (SPC) for large volumes

How to Choose a Precision Machining Partner

- Experience with aluminium-specific processes

- Capabilities in 3D CAD/CAM integration

- Tooling and fixture customisation

- In-house quality assurance systems

- Certifications (ISO, AS9100 for aerospace, etc.)

Future of Precision Machining in Aluminium

With the rise of EVs, lightweight construction, and aerospace advancements, demand for precision machining is growing. AI-driven machining, real-time monitoring, and additive-subtractive hybrids are set to transform how aluminium assemblies are made. Precision is no longer optional—it’s a competitive necessity.

Conclusion

Precision machining plays a defining role in the success of aluminium extrusion assemblies. From structural performance to aesthetic perfection, it impacts every phase of a product’s lifecycle. By investing in quality processes and skilled partners, manufacturers can ensure their aluminium components meet the highest standards of modern engineering and design.

Disclaimer

This article is for informational purposes only and does not constitute engineering advice. ALUTimes publishes neutral and research-based content. For application-specific solutions, consult with certified aluminium fabrication experts.