Common Anodizing Defects

Published by: ALUTimes | Date: July 10, 2025

Introduction

Anodizing aluminium enhances its durability, corrosion resistance, and aesthetics. However, the process isn’t foolproof. Improper techniques or poor quality control can result in various defects. In this article, we’ll explore the most common anodizing defects, their causes, and proven strategies to avoid them.

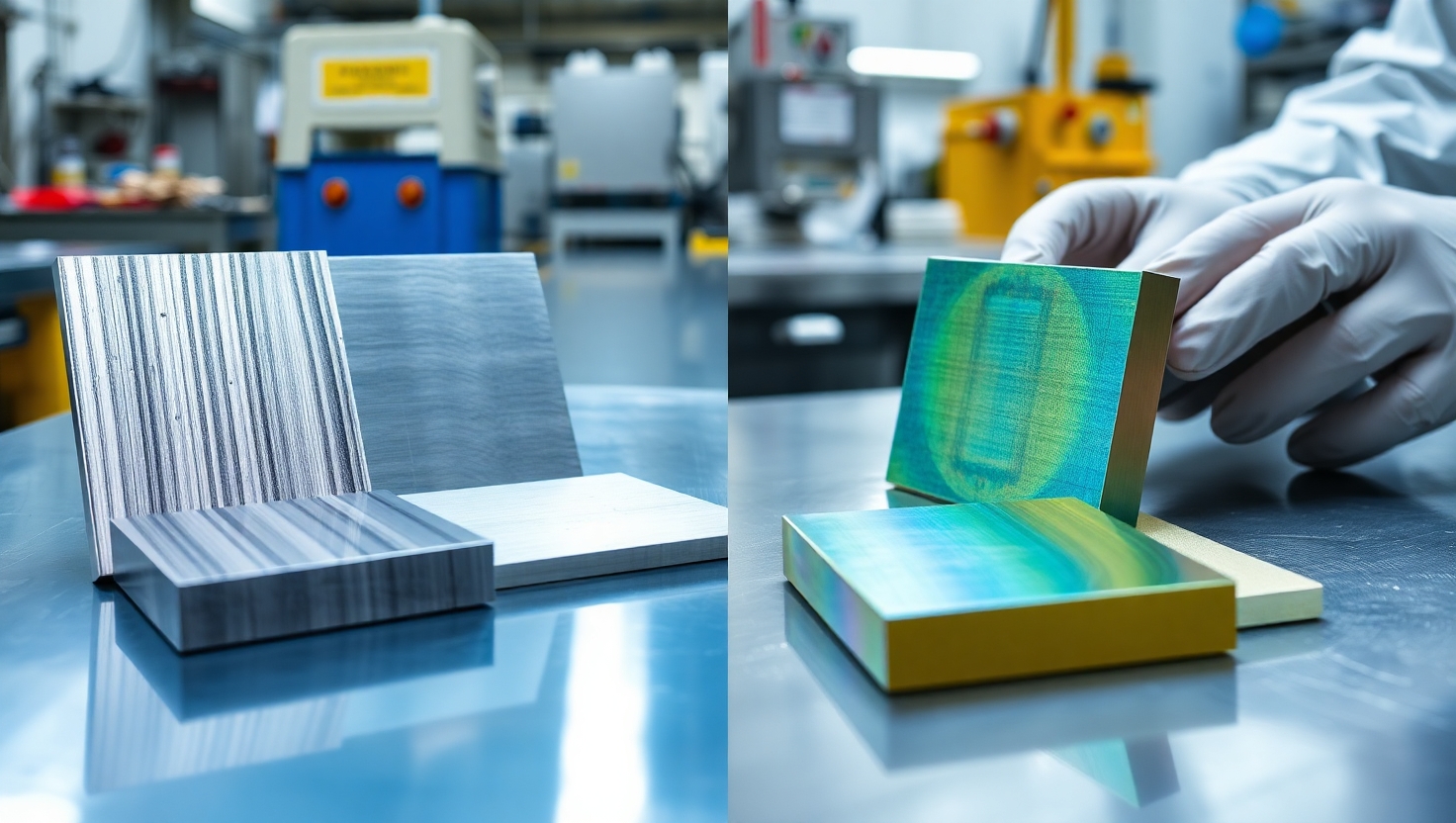

1. Streaks and Smut Marks

What It Is: Uneven lines or black marks that appear after anodizing.

Causes: Improper cleaning, etching inconsistencies, or inadequate rinsing before anodizing.

How to Avoid: Ensure thorough pre-treatment and de-smutting. Maintain clean tanks and proper etch time control.

2. Pitting and Pinholes

What It Is: Small holes or craters on the aluminium surface.

Causes: Contaminants in the electrolyte, improper rinsing, or surface defects in raw material.

How to Avoid: Use high-purity aluminium, deionized water, and monitor bath contaminants closely.

3. Poor Adhesion of Dyes or Seal

What It Is: Inconsistent color absorption or flaking of sealant.

Causes: Incomplete anodic layer formation or premature sealing.

How to Avoid: Monitor anodizing time and current density. Don’t rush the sealing phase.

4. Color Variations

What It Is: Uneven coloring or batch-to-batch inconsistencies.

Causes: Fluctuating current, dye concentration, temperature, or alloy variations.

How to Avoid: Standardize process parameters. Use consistent alloy types and calibrate dye tanks regularly.

5. Burn Marks

What It Is: Dark, damaged patches caused by overheating during anodizing.

Causes: Excessive current density, poor agitation, or high bath temperature.

How to Avoid: Use proper racking and spacing. Control temperature and maintain adequate solution circulation.

6. Powdery or Chalky Finish

What It Is: Dull, soft, or powdery surface after anodizing.

Causes: Over-anodizing or skipping sealing step.

How to Avoid: Stick to recommended anodizing times and always seal parts effectively.

7. Excessive Etch Loss

What It Is: Loss of dimensional tolerance due to aggressive etching.

Causes: Overexposure to alkaline etching solutions.

How to Avoid: Monitor etch bath pH and limit etching duration. Use controlled agitation.

8. Scaling or Flaking

What It Is: Surface peeling post-anodizing.

Causes: Inadequate surface preparation or sealing failure.

How to Avoid: Ensure proper cleaning, sealing, and avoid exposing anodized parts to extreme mechanical stress too soon.

Conclusion

Understanding and preventing anodizing defects is crucial for delivering high-quality aluminium components. By maintaining strict process controls and investing in operator training, manufacturers can reduce waste, improve finish consistency, and meet end-user expectations.

Disclaimer

This article is intended for educational purposes only. For specific process standards and industrial guidance, consult a certified anodizing expert or standards authority.